MakBoxGrand Block-modular local treatment plants with a capacity of 50-1000 m3/day

The MakBoxGrand treatment plant unit consists of a rectangular underground reinforced concrete part divided by walls into treatment zones and a ground building (rectangular container) with technological equipment located near the underground (tratment) part. Operational access is carried out through technological throats (rectangular hatches).

The technological scheme provides for the following composition of the main structures:

- stage of preliminary mechanical cleaning;

- averager;

- denitrifier;

- bioreactor with attached biocenosis;

- aeration tank;

- secondary settling tank;

- additional treatment reactor;

- well with pump;

- sand-gravel filter;

- compressor unit;

- aerobic stabilizer;

- hypochlorite dosing unit;

- sludge dewatering unit.

Order treatment facilities

Domestic wastewater flows through a self-flowing pipeline to thedamping well, from which it enters the stage of mechanical treatment. Captured waste is periodically removed from the grate into the basket, as the waste is filled, it is taken to the landfill for solid waste (LSW). Further wastewater enters the averager. Prevention of the sedimentation of suspended solids in the averager is achieved by the supply of air by the compressor through the aerators. In the averager, in a special basket, the pump which on timer carries out even supply of wastewater for biological treatment is arranged.

From the averager, the wastewater enter the denitrification zone, where biological treatment in the oxygen-free regime and mixing of wastewater takes place to prevent the accumulation of sediment at the bottom of the denitrifier. Mixing takes place with the help of disk aerators arranged at the bottom of the denitrifier tank. Then there is biological treatment with the addition of oxygen. Air to the aeration tank and to the denitrification zone is supplied by the compressor unit through a system of aerators.The process of sorption, oxidation of organic substances and the process of nitrification takes place in the aeration tank. A necessary condition for biological treatment is the recirculation of activated sludge, which is fed into the denitrification zone by means of pumps arranged in the aeration tank and in the secondary settling tank. For greater efficiency of sewage treatment in the aeration tank biological loading is arranged.

Biologically treated wastewater enters the secondary settling tank. It separates the sludge mixture into water and activated sludge. The latter is pumped back to the denitrifier.

After the secondary settling tank, the stage of additional treatment of wastewater in the reactor with attached plastic loading is provided. Air supply is carried out by the compressor unit through aerators.

The treated wastewater enters by gravity for additional treatment by means of disinfection with sodium hypochlorite. The wash water formed during the washing of the sand-gravel filter is discharged into the mechanical treatment unit. The filter is washed periodically as it gets dirty.

Excess activated sludge is pumped from the secondary settling tank to the aerobic stabilizer and to the aeration tank.

Excess biofilm from the additional treatment reactor by airlift is pumped to the aerobic stabilizer.Floating substances from the surface of the secondary settling tank and the additional treatment reactor are periodically removed through the funnel to the averager. Stabilized activated sludge and biofilm from the aerobic stabilizer are pumped to the sludge dewatering unit in which there is a gravitational dewatering of sludge in hydrophobic bags. The filter water formed as a result of dewatering is returned to the averager.

After dewatering, the sludge in bags is additionally dried and taken to the landfill under a separate agreement.

The treatment process is controlled from the central control panel located in the modular house. The control panel includes an electricity meter and a GSM alarm unit. The modular house is equipped with a heating system with electric radiators, lighting, ventilation system.

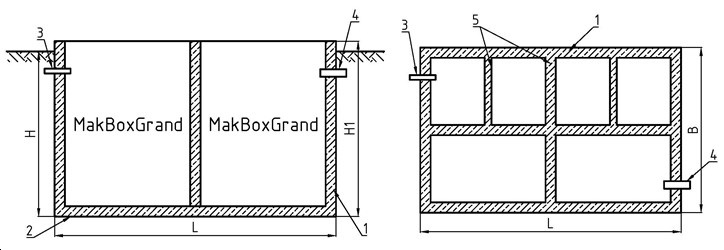

Scheme of MakBoxGrand biological treatment plant, designed to serve from 250 to 5000 people.

1 – case; 2 – bottom; 3 –inlet brach pipe; 4 – outlet branch pipe, 5 – partitions.

L – length of the treatment plant case; В – width of the treatment plant case; H – working height of treatment plant; W – height of outlet branch pipe; H1 – total treatment plant height.

Overall dimensions table

| Model of station | Capacity, m3/day | Users, people | Working volume, m3 | Electricity, kW/hour | Width B, mm | Length L, mmм | Working height Н, mm | Total height Н1, mm |

| MakBoxGrand-50 | 50 | 250 | 62,0 | 3,0 | 5200 | 9600 | 2300 | 2800 |

| MakBoxGrand-100 | 100 | 500 | 130,0 | 7,0 | 6600 | 11100 | 3000 | 3500 |

| MakBoxGrand-200 | 200 | 1000 | 280,0 | 13,0 | 9800 | 14900 | 3500 | 4000 |

| MakBoxGrand-500 | 500 | 2500 | 670,0 | 26,0 | 14100 | 19800 | 3500 | 4000 |

| MakBoxGrand-1000 | 1000 | 5000 | 1280,0 | 60,0 | 17900 | 28100 | 4000 | 4500 |