Grit chambers. Selection and use

Quite often, at the stage of mechanical treatment, wastewater enters the grit chambers. They are designed to retain mineral suspensions, mainly sand with a size of 0.2 – 0.25 mm or more. As a result of sand retention facilitates the operation of treatment plants. Light particles of organic origin should be removed from the grit chambers. The work of the grit chamberp is based on the use of gravitational forces.

Today the following types of grit chambers are used:

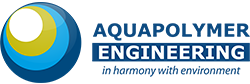

- Horizontal grit chamber. In the expanded part of the tank under the action of gravity there is a sedimentation of sand. The speed of water movement in the grit chamber is 0.15 – 0.3 m/sec. At a speed of more than 0.3 m/sec the sand does not have time to settle, and at a speed of less than 0.15 m/sec organic impurities begin to settle, that is unacceptable. The residence time of wastewater in the grit chamber is 0.5 – 2 minutes.

- Vertical grit chamber. Vertical orientation of the tank. Water gets inside and loses speed, sand settles to the bottom of the tank. It consists of a settling and working part.

- Aerated grit chamber. Along one of the walls at a distance of 45 – 60 mm from the bottom along the entire length arrange aerators in the form of perforated pipes with holes 3 – 5 mm. The air promotes the rotation of water and thus increases the effect of sedimentation. Used in cases where the most complete separation of impurities by size is required.

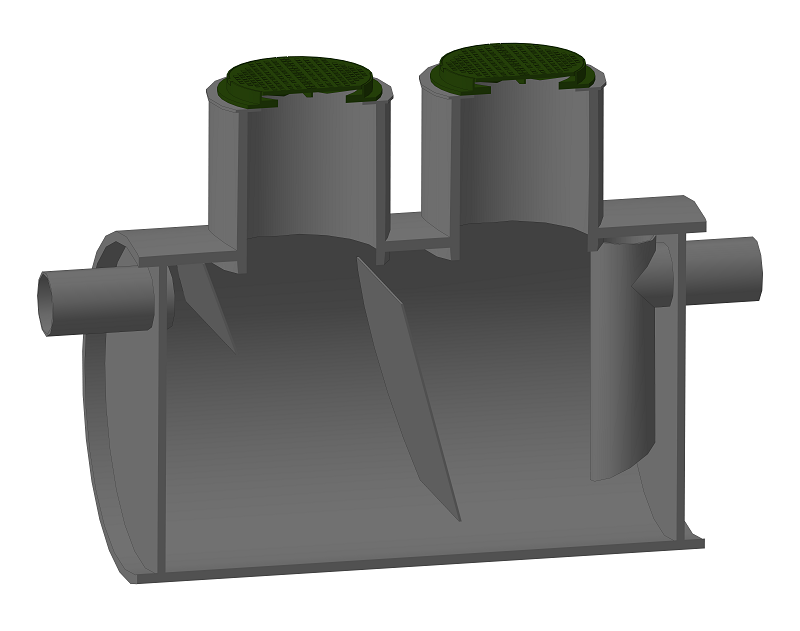

- Tangential grit chamber. Round, with a small depth of the flowing part. Water supply is carried out tangentially. A rotational motion is formed, which promotes the washing of sand from organic substances, preventing their precipitation.

Sand trapped in grit chamber is usually removed from them by hydraulic elevators (jet water pumps), conveyer/auger or manually.

Buy sand trap

You can buy a sand trap on our website. Aquapolymer Engineering company has been a manufacturer of sand traps on the Ukrainian market for over 9 years. To order, call the