Grease separators for sewer systems of restaurants, sinks, houses. Industrial grease separators

Grease separators MakBoxF

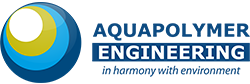

There are 4 main options:

- Grease separator MakBoxFit (from 0.1 up to 5 l/s). Made of polypropylene. It is installed indoors.

- Grease separator MakBoxFat-N (from 1 up to 10 l/s). Made of polypropylene. It is installed in standard reinforced concrete rings or a reinforced concrete pit of necessary diameter.

- Grease separator MakBoxFat (from 1 up to 15 l/s). Made of reinforced polypropylene. It is installed directly into the ground without additional concreting in green and pedestrian areas.

- Grease separator MakBoxFat-C (from 1 до 10 l/s). Made of reinforced concrete with an inner polypropylene wall.It is installed in any soil under driveways and highways (load class up to D400). The height is regulated by standard reinforced concrete rings and a floor slab with a hatch.

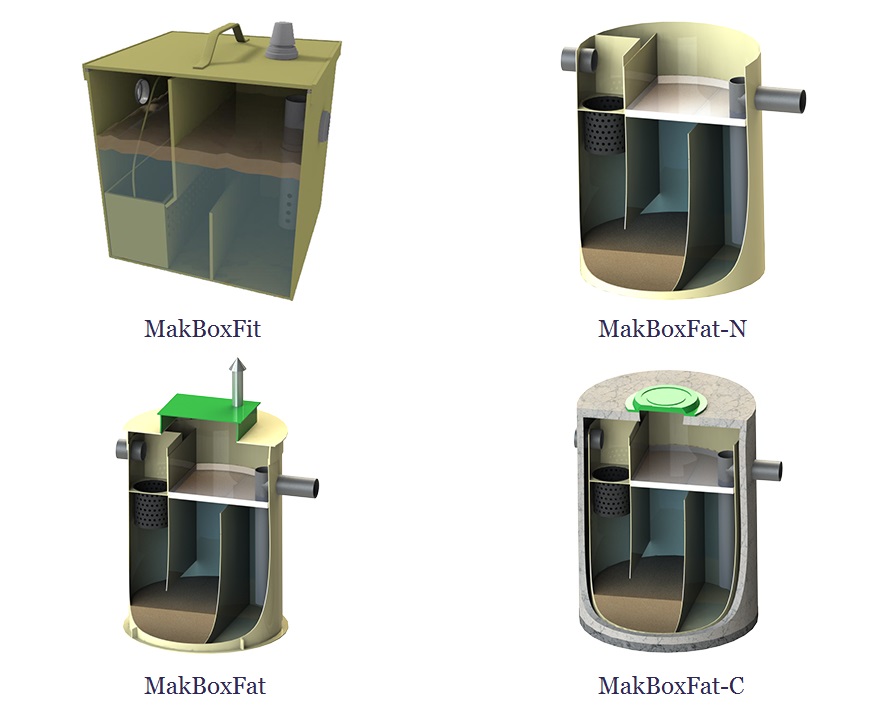

Technology of grease-containing wastewater treatment

Our company’s engineers have developed a modern wastewater technology for grease.

First, the wastewater enters the basket (1) through the inlet pipe, where large (solid) contaminants are remained. If the equipment of the separator does not include a basket, then the largest contaminants accumulate in the solid waste compartment (2), where they are gravitationally separated from the wastewater.

Next, the ascending flow, due to the partitions, the water rises. The grease particles combine with each other and float up to the grease accumulation area (3).

Grease-treated wastewater flows downstream into the overflow pipe and is discharged to the sewer system.

Separator operation (depending on the composition of grease-containing substances)

- Extract of solid waste from the basket or from the solid waste compartment – once a month.

- Extract of grease by mechanical means (scoop), a special pump – from 1 time per week to 1 time per quarter (depending on the modification of the grease separator).

- Flushing the separator with a flushing system – once a quarter.

* Additional equipment

Built-in pumping station, pumping pipe, flushing system with pump.

Overall dimensions table

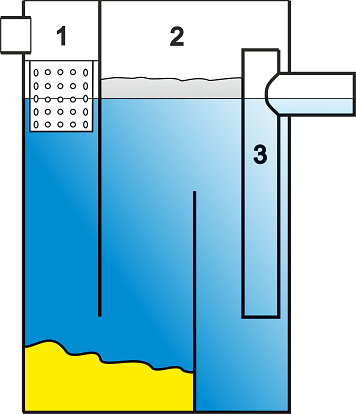

1 – case; 2 – bottom; 3 – cover; 4 – inlet branch pipe; 5 – outlet branch pipe.

L –case length; D – case diameter; В – case width; H – working height; k – height of inlet branch pipe; n – height of outlet branch pipe; H1 – overall height; Ду – diameter of connections.

Effluent volume, l/s, Total volume, l, Max. Grease volume, l, Massа, кг, Diameter(D), Length (L) / Width(В), мм,

Height (Н), mm Inlet (k), mm Outlet (n), mm D of inlet and outlet, mm

| MakBoxF | Volume of drains, l / s | Total volume, l | The maximum volume of fats, l | Weight, kg | Diameter (D), Length (L) / Width (B), mm | Height (H), mm | Input (k), mm | Output (n), mm | Inlet and outlet diameter,mm |

|---|---|---|---|---|---|---|---|---|---|

| Model | |||||||||

| MakBoxFit – grease separator for the premises, installation insidoors | |||||||||

| MakBoxFit-0,1 | 0,1 | 44 | 15 | 5 | 400/400 | 400 | 300 | 275 | 50 |

| MakBoxFit-0,2 | 0,2 | 69 | 26 | 8 | 500/500 | 400 | 300 | 275 | 50 |

| MakBoxFit-0,3 | 0,3 | 103 | 45 | 12 | 750/500 | 400 | 300 | 275 | 50 |

| MakBoxFit-0,4 | 0,4 | 141 | 75 | 15 | 750/500 | 500 | 400 | 375 | 50 |

| MakBoxFit-0,5 | 0,5 | 188 | 106 | 20 | 1000/500 | 500 | 400 | 375 | 50 |

| MakBoxFit-1 | 1 | 424 | 252 | 25 | 1000/750 | 750 | 590 | 565 | 110 |

| MakBoxFit-2 | 2 | 593 | 362 | 30 | 1400/750 | 750 | 590 | 565 | 110 |

| MakBoxFit-3 | 3 | 1141 | 713 | 35 | 1400/100 | 1000 | 840 | 815 | 110 |

| MakBoxFit-4 | 4 | 1499 | 966 | 40 | 1400/1400 | 1000 | 790 | 765 | 160 |

| MakBoxFit-5 | 5 | 1721 | 1125 | 45 | 1500/1500 | 1000 | 790 | 765 | 160 |

| MakBoxFat – the usual grease separator, strengthened (-N – installation in reinforced concrete rings) | |||||||||

| MakBoxFat-1 | 1 | 524 | 181 | 25 | 950 | 1000 | 790 | 740 | 110 |

| MakBoxFat-2 | 2 | 701 | 258 | 30 | 950 | 1250 | 1040 | 990 | 110 |

| MakBoxFat-3 | 3 | 1402 | 557 | 40 | 1200 | 1500 | 1290 | 1240 | 110 |

| MakBoxFat-4 | 4 | 1579 | 637 | 45 | 1300 | 1500 | 1240 | 1190 | 160 |

| MakBoxFat-5 | 5 | 1831 | 723 | 50 | 1400 | 1500 | 1240 | 1190 | 160 |

| MakBoxFat-6 | 6 | 2894 | 1189 | 60 | 1600 | 1750 | 1490 | 1440 | 160 |

| MakBoxFat-7 | 7 | 3834 | 1716 | 70 | 1700 | 2000 | 1740 | 1690 | 160 |

| MakBoxFat-8 | 8 | 4298 | 1980 | 80 | 1800 | 2000 | 1740 | 1690 | 160 |

| MakBoxFat-9 | 9 | 4789 | 2261 | 90 | 1900 | 2000 | 1740 | 1690 | 160 |

| MakBoxFat-10 | 10 | 5045 | 2409 | 95 | 1950 | 2000 | 1740 | 1690 | 160 |

| MakBoxFat-С – grease separator made of reinforced concrete | |||||||||

| MakBoxFat-C-1 | 1 | 620 | 206 | 1250 | 1200 | 1200 | 990 | 940 | 110 |

| MakBoxFat-C-3 | 3 | 1091 | 470 | 1750 | 1200 | 1800 | 1590 | 1540 | 110 |

| MakBoxFat-C-6 | 6 | 2367 | 1042 | 3000 | 1700 | 1800 | 1540 | 1490 | 160 |

| MakBoxFat-C-8 | 8 | 4208 | 1708 | 4550 | 2200 | 1800 | 1540 | 1490 | 160 |

Buy grease grease separator

You can buy a grease separator on the website of Aquapolymer Engineering. Order / consultation by phone 067 245 88 89 or leave a request on our website.