Plastic wells are objects of external engineering networks, designed for drainage, inspection and cleaning of the system, to change the direction of the network. Wells are used when it is necessary to change the diameter and the difference when laying pipes.

They are prefabricated and welded, sewer and inspection, stormwater and drainage. Today, polypropylene, polyethylene and unplasticized polyvinyl chloride are widely used for their production. Today, plastic wells are becoming increasingly popular as a profitable alternative to concrete wells.

The diameter of the products starts from 300 mm. If the diameter of the well is less than 800 mm, they are not designed for human penetration and are serviced from the ground by special equipment. In a well with a diameter of more than 800 mm, human penetration is possible, in the absence of modern equipment to service the system from the ground.

Inspection wells are most often used. An inspection well or chamber is a mine located above a drainage or sewer pipeline, inside which the pipe or collector is replaced by an open tray. The purpose of these wells is to control the operation of the entire system, providing the possibility of cleaning, ventilation and other various operational measures. On the basis of the data received as a result of visual inspection, the decision on cleaning and other necessary works is made.

Installation of inspection wells is required:

- in places of change of diameter or a slope of the pipeline;

- when changing the direction of flow;

- at the junctions of the side connections;

- on straight sections, at distances convenient for operation (in 35-300 m depending on diameter of the pipeline).

Depending on the purpose, inspection wells are divided into linear, rotary, nodal and control. In addition, flushing, height difference and special wells are used. Each of the wells of this type has its own purpose. However, the solution of several tasks can be provided in one structure. It is mandatory to mark the top of the hatch, which determines the type of sewer communications.

By arrangement, all plastic inspection wells are of the same type, as a rule, the difference can occur only in the depth of occurrence. They can be made prefabricated or welded. All their parameters are quite strictly standardized. We advise you to buy wells in full, without giving up important details for the sake of economy.

When choosing plastic wells you get many significant advantages:

- resistance to aggressive, alkaline and acidic environments;

- high strength of the material and the entire structure;

- wear resistance;

- high passability;

- light weight of products;

- guaranteed environmental safety;

- increased impact resistance and resistance to external mechanical loads;

- no additional waterproofing is required;

- production according to individual sizes;

- the possibility of extensionof a mine and throat;

- no special equipment is required;

- durability (in acceptable conditions does not require repair for at least 50 years);

- ease of transportation.

Consider several options for engineering wells.

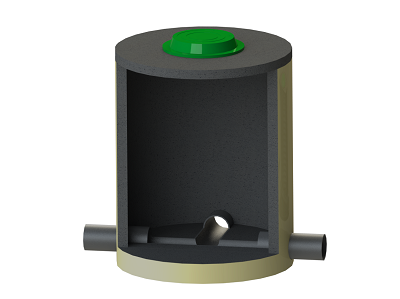

- Reinforced concrete well with inner or outer plastic wall.

The well is a completely sealed reinforced concrete cup with a plastic (inner or outer) wall with an inner diameter of 800, 1000, 1500, 2000 mm and a height of 700 to 1800 mm. To deepen such a cup to any depth, standard reinforced concrete rings and a floor slab of appropriate diameter with a hatch are additionally installed.

The inner tray part can be made of standard polyethylene pipes PE-80 SDR-33 of any diameter, pipes of the Corsis type and sewer inserted-joint PP pipes. It is possible to complete any branch pipes, hubss, couplings, check valves, etc. for a specific project of the.

Advantages: guaranteed tightness, durability of reinforced concrete to D 400, low price,

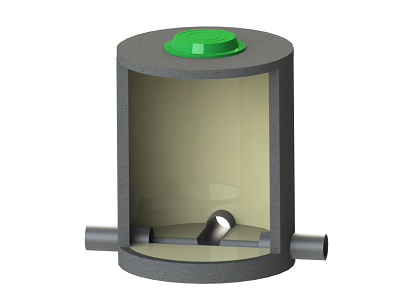

- Well with a cellular polyethylene wall

This type of well is made of polyethylene pipe by the method of winding (cellular structure), thanks to which maximum tightness and high strength are achieved. The sizes of wells can be any – diameter from 0.6 to 3 meters and height from 0.5 to 15 meters. The tray part can be made of PE-80 SDR-33 polyethylene water pipes of any diameters and sewer pipes of the Corsis type in any variants.

Advantages: guaranteed tightness, light and strong structure, any sizes and options of insertion and connection of pipelines.

- Polyethylene well prefabricated rotary

The well is made of polyethylene by rotational molding and consists of several parts (tray, extension, throat, hatch), which are welded together.

The well can be mounted at great depth, the required height of the tank is achieved due to extensions.

Delivery and installation

A typical well is delivered in a ready factory complete set. This minimizes delivery,

The atypical project is also completed entirely in the factory. At its development it is necessary to consider height and width of a well; diameter, height and number of inserts, type of bottom and hatch.

Buy engineering wells

You can buy an engineering well in the Aquapolymer Engineering company. We have more than 9 years of experience. To order, call tel. 067 245 88 89 or leave a request on our website.