Rainwater treatment (Rainwater drainage)

MakBoxRain (oil separators)

What are oil separators and how they are used?

Oil separators – special filtration devices used in parking lots, gas stations, oil refineries, on the farm, in the construction of storm sewers, etc. Their purpose is to remove suspended solids and particles of petroleum products from surface wastewater by filtration and settling.

Typically, oil separators are combined with grit chambers in a single housing to avoid problems with solids and sludge removal. The standard system consists of three compartments through which contaminated water passes.

All systems are classified into several types, according to the design:

- Horizontal;

- Radial;

- Multilevel.

The most common are horizontal oil separators. These are large tanks with parallel compartments separated by partitions. wastewater from the distribution system passes through each section, and only then is sent to the sewer or used in another way.

Advantages of oil separators for rainwater treatment

The main advantages of using modern oil traps are as follows:

- Efficiency. High-quality cleaning systems filter most impurities without additional pumps and chemical reagents.

- Availability. The cost of separators is a small cost compared to their benefits in industry, economy and the environment.

- Practicality. All accumulated impurities are stored in separate chambers, after which they are convenient to dispose of in a special container.

- Ecology. Wastewater treatment before further use prevents soil and water pollution with petroleum products.

- Unpretentiousness. Modern cleaning systems do not require complex maintenance.

MakBoxRain oil separators

There are four main models of MakBoxRain rainwater treatment separators:

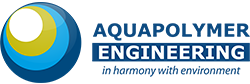

MakBoxRain-N (up to 15 l/s). Polypropylene. It is installed on typical reinforced concrete rings or pits of the corresponding diameter

MakBoxRain-C (up to 10 l/s). Reinforced concrete with an inner polypropylene layer. It is established in any soils when arranging highways and passages of D-class of loading. Reinforced concrete rings and slabs for height adjustment

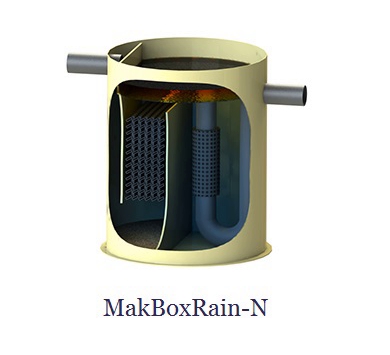

MakBoxRain -K (from 1 up to 400 l/s). Polyethylene. Installed directly into the ground, under the driveways – inclusive. Does not require concreting

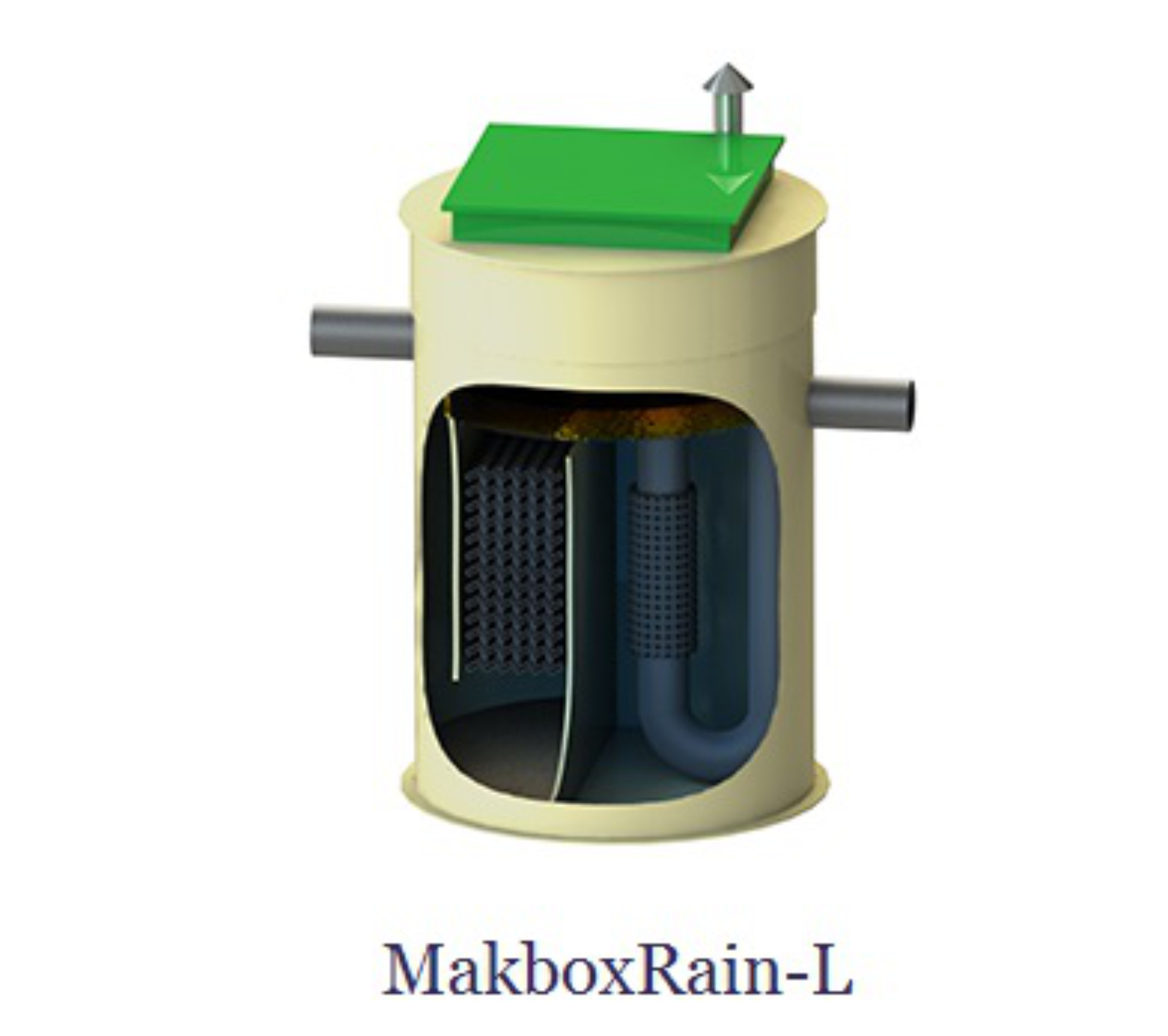

MakBoxRain -L (up to 15 л/с). Reinforced polypropylene. Installed directly into the ground in green or pedestrian areas. Does not require concreting

These oil separatorss are designed to treat wastewater with the MPC of suspended solids 70 mg / l for all models and petroleum products – 70 mg/l and 200 mg/l depending on the model.

Patented rainwater treatment technology

- To filter solid particles and sand, wastewater enters the pipeline, which enters the grit

- Coalescent polymer filter 2H-Plast acts as an oil separator that traps impurities of petroleum products. They connect with each other and float upwards under the influence of upward flow.

- In some cases, a mechanical float is used, which allows you to visually control the level of floating petroleum products. It is equipped with a special pipe in case of emergency overflow or for sampling.4. U-filter is a polypropylene strainer that provides the second stage of filtration. It serves as the final oil trap for wastewater treatment from the remaining impurities.

- U-filter is a polypropylene screen filter that provides the second stage of filtration. It acts as the final oil separator for wastewater treatment from the remaining impurities.

After the U-filter, the treated wastewater enters the outlet.

The oil trap is serviced as follows:

- Cleaning the sand trap from sand – every six months with a special pump;

- Cleaning of the filter from petroleum products – every quarter by means of pumps, sorbing mats or an electric skimmer;

- Flush the filter with clean water – every two years;

- Flush the second screen filter with clean water – every year.

The frequency depends on the conditions of use of the separator and on the composition and condition of rainwater in the region.

Additional components can be used for more efficient wastewater treatment:

- Built-in backup bypass for stream redirection;

- Sampling unit;

- Sorbent mats for petroleum products;

- Automated unit for monitoring the level of petroleum products and sand;

- Skimmer for pumping oil products, etc.

Buy oil separator

You can order an oil separator in Aquapolymer Engineering. Call no. 067 245 88 89. Our specialists will advise you on all issues.

Selection and use of oil separators

The MakBoxRain-K oil separator is used to arrange the drainage of filtered wastewater to the storm sewer. It is enough to meet the standard: for suspended solids – 15.0 mg/l, for petroleum products – 0.3 mg/l. Such water can be used in fire storage tanks and for irrigation.

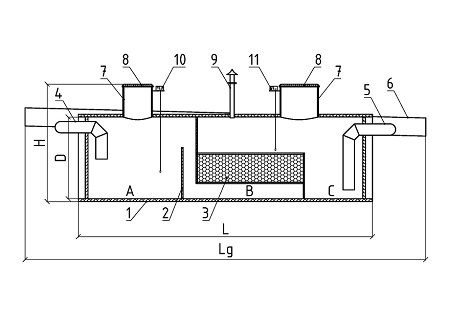

Scheme of surface wastewater treatment plant for suspended solids, sand and petroleum products, MakBoxRainK model with a capacity of 1.0 to 400.0 l/s.

1 – case; 2 – partition between compartments; 3 – coalescent filter; 4 – inlet branch pipe; 5 – outlet branch pipe; 6 – bypass; 7 – throat; 8 – hatch; 9 – ventilation pipe; 10 – sediment level indicator; 11 – в;petroleum products level indicator

L – case length; Lg – overall length; D – inner diameter of case; Н – overall height; А – receiving compartment (area of deposition of suspended solids and sand); В – filter compartment (petroleum products separation area); С – outlet compartment (complete treatment area).

Note: The ventilation pipe and bypass are mounted on a mounted MakBoxRainK oil separator.

Для облаштування відводу фільтрованої стічної води до водних об’єктів використовується додатковий сорбуючий фільтр MakBoxRain-S. Норматив для водних об’єктів рибогосподарського призначення: за завислими речовинами – 5,0 мг/л, за нафтопродуктами – 0,05 мг/л.

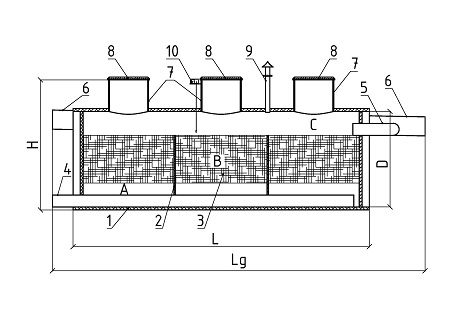

Scheme of surface wastewater treatment plant for suspended solids, sand and petroleum products, MakBoxRainS model with a capacity of 1.0 to 400.0 l/s.

1 – case; 2 – partition between filter elements; 3 – sorption filter; 4 – inlet branch pipe; 5 – outlet branch pipe; 6 – bypassс; 7 – throat; 8 – hatch; 9 – ventilation pipe; 10 – sand and petroleum products level indicator;

L – case length; Lg – overall length; D – inner diameter of case; Н – overall height; А – lower compartment(suspended solids separation area); В – middle compartment(petroleum products separation areaв); С – upper compartment(purified water drainage area).

Note: The ventilation pipe and bypass are mounted on a mounted MakBoxRainS oil separator

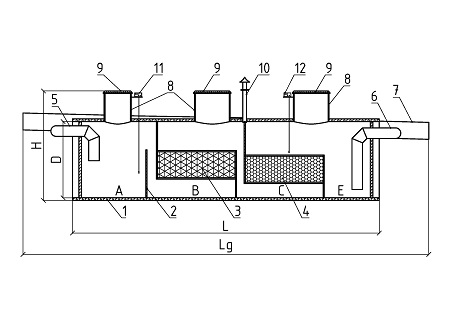

iSignificant content of sand or suspended petroleum products (more than 200 mg/l) requires installation with an additional volume of grit chamber and a thin-layer filter for better sedimentation of sand MakBoxRain-T, which is designed to treat effluents with the MPC of petroleum products 70 mg/l for all models and suspended solids – 200 mg/l, 500 mg/l, 1000 mg/l depending on the model.

Scheme of surface wastewater treatment plant for suspended solids, sand and petroleum products, MakBoxRainT model with a capacity of 1.0 to 400.0 l/s.

1 – case; 2 – partiotion between compartment; 3 – thin-layer filter ; 4 – coalescent filter ; 5 – inlet branch pipe; 6 – outlet branch pipe; 7 – bypass; 8 –throat; 9 – hatch; 10 – ventilation pipe; 11 – sediment level indicator; 12 – petroleum products level indicator;

L – case length; Lg – overall length; D – внутрішній діаметр корпуса; Н – габаритна висота; А – receiving compartment (sand sedimentation area); В – first filter compartment (suspended solids separation and sedimentation area); С – second filter compartment (petroleum products separation area); Е – outlet compartment (area of complete treatment).

Note: The ventilation pipe and bypass are mounted on a mounted MakBoxRainT oil separator

An additional MakBoxRain-NA treatment unit is installed to arrange the return water supply system when using filtered water for technical needs or, for example, a car wash. It consists of a pressure floater, a disinfection unit, an additional sand-gravel filter and automation.

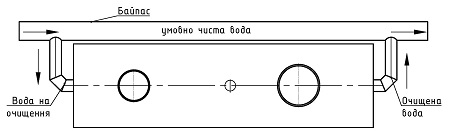

Use of bypass for storm sewer

The built-in bypass is used to reduce power in the system.

When rainwater enters, the first contaminated portion of rain enters the oil separator. If the amount of rainwater increases, its relatively clean part is sent immediately to the sewer network, past the separator. The flow is regulated by a proper valve.

Various atypical complete sets of filters and separators are also possible, depending on needs, operating conditions, volumes and specifics of works. The sizes of separate compartments and blocks are varied, additional branches and hatches are added, tanks for the cleared water are built in, etc.

Main dimensions and technical characteristics of MakBoxRain K-70.

|

Model label

|

Productivity max., L/s

|

D, мм

|

Length,

L mm

|

Total length, Lg mm

|

Height, Н mm

|

Number of necks, pieces

|

Theoretical mass, kg

|

|

MakBoxRainK 70-1

|

1

|

1200

|

2100

|

4050

|

2050

|

1

|

350

|

|

MakBoxRainK 70-3

|

3

|

2750

|

4750

|

2

|

450

|

||

|

MakBoxRainK 70-5

|

5

|

3050

|

5100

|

500

|

|||

|

MakBoxRainK 70-7

|

7

|

3400

|

5500

|

600

|

|||

|

MakBoxRainK 70-10

|

10

|

1600

|

3000

|

5100

|

2460

|

800

|

|

|

MakBoxRainK 70-15

|

15

|

3400

|

5500

|

850

|

|||

|

MakBoxRainK 70-20

|

20

|

3700

|

5900

|

950

|

|||

|

MakBoxRainK 70-25

|

25

|

1800

|

3800

|

6000

|

2650

|

1100

|

|

|

MakBoxRainK 70-30

|

30

|

4300

|

6500

|

1200

|

|||

|

MakBoxRainK 70-35

|

35

|

4800

|

7000

|

1300

|

|||

|

MakBoxRainK 70-40

|

40

|

5300

|

7500

|

1500

|

|||

|

MakBoxRainK 70-45

|

45

|

5800

|

8100

|

1600

|

|||

|

MakBoxRainK 70-50

|

50

|

6400

|

8700

|

1800

|

|||

|

MakBoxRainK 70-55

|

55

|

6900

|

9200

|

1900

|

|||

|

MakBoxRainK 70-60

|

60

|

7500

|

9800

|

2000

|

|||

|

MakBoxRainK 70-65

|

65

|

2000

|

6900

|

9200

|

2900

|

2500

|

|

|

MakBoxRainK 70-70

|

70

|

7200

|

9500

|

2600

|

|||

|

MakBoxRainK 70-80

|

80

|

7800

|

10300

|

2800

|

|||

|

MakBoxRainK 70-90

|

90

|

8600

|

11000

|

3200

|

|||

|

MakBoxRainK 70-100

|

100

|

9300

|

11700

|

3400

|