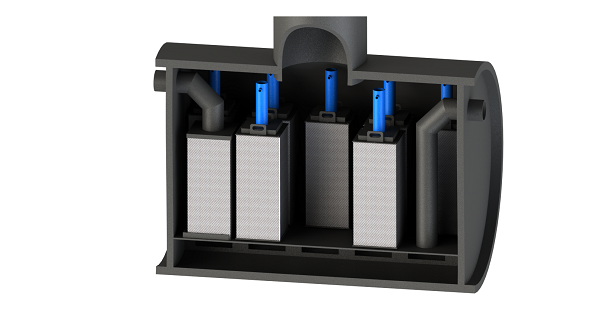

The filter is designed to purify rain and melt water from petroleum products and suspended solids. The sorption filter is used only in combination with other treatment systems (grit chamber and coalescent filter) to achieve the best cleaning performance at the outlet of treatment plants.

Depending on the task of the customer (degree of cleaning) filters are made with two types of cases of filtering elements:

- Metal (stainless steel)

- Combined (polypropylene, polyethylene with stainless steel elements)

Filter blocks are made by a combination of materials of mechanical (coalescence) and ion-exchange treatment

As materials are used:

- synthetic fibers (polypropylene, lavsan, synthetic winterizer);

- polystyrene (foam balls);

- activated carbon (of different porosity and fraction);

- zeolite (Transcarpathian, of different porosity and fraction).

Filter blocks are partially regenerable, namely:

- Mechanical backwash with purified water;

- Regeneration by back-passing water vapor through carbon and zeolite filling

It is forbidden to use a filter for water purification containing other pollutants of non-oil origin. When using a sorption filter manufactured by Aquapolymer Engineering at the outlet of treatment plants, the following indicators of rain and melt water treatment can be achieved: suspended solids – 5 mg /l, petroleum products – 0.05 mg /l.