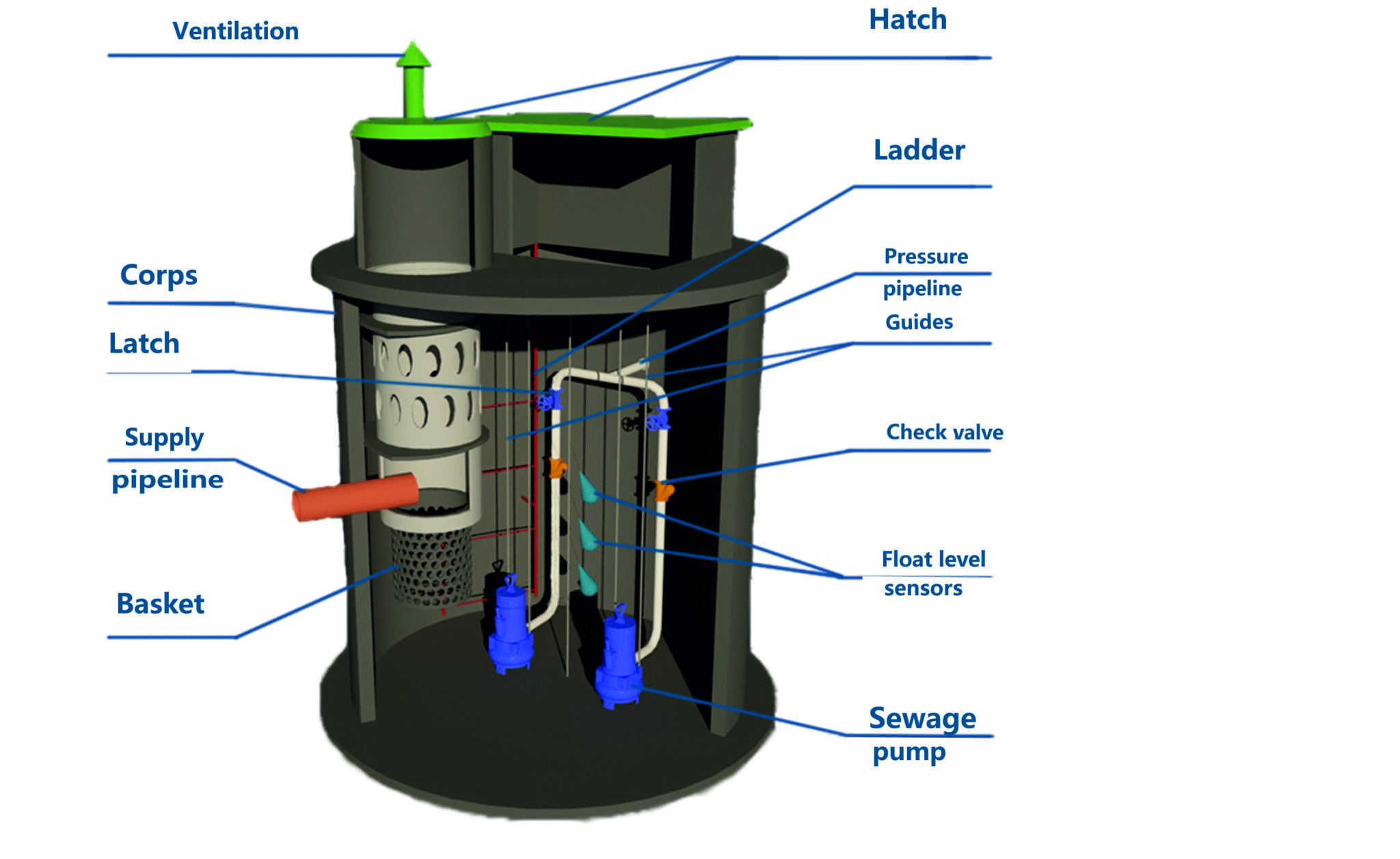

To ensure that the sewage pumping station always remains efficient and reliable, it is important to ensure proper comprehensive maintenance. The efficiency of the system, its environmental friendliness and functionality depend on it.

– Maintenance is carried out at least once a quarter;

– It is necessary to systematically monitor the operating cycles of all pumps;

– The appearance of strange noise at work – one of the first signs of failure;

– In the presence of the smallest deviations, all hydraulic indicators are checked to reveal a source of a problem;

– In case of significant malfunctions, the pump must be promptly replaced or repaired;

– All pumps are periodically removed alternately for cleaning and washing; – Do not use cables for lifting to avoid accidents or serious damage; – The pumps are carefully inspected for damage, signs of wear and other defects.

Work order

One of the first stages of cleaning works is cleaning of wells. Sludge and accumulated waste are removed from them. If there are too many waste, the pumping equipment fails and the whole station stops. This, in turn, threatens emergencies, serious environmental problems and expensive overhauls.

To avoid a trouble, it is important to service sewage pumping stations professionally and on time. During cleaning, all waste, solid particles, liquid effluents that have accumulated in the blocks are removed.

Vacuum pumps and other professional equipment are used for pumping. This is a simple and fast method of cleaning, which allows you to remove even serious clogging at a considerable depth. Waste disposal is carried out at special landfills.

Chemical detergents are used to clean the inner surface from grease and oil products. The oil level is also checked and restored.

The work of the SPS is strictly regulated. All processes take place in accordance with regulatory and technical documentation. Therefore, to control the operating condition of the pumps is quite simple: it is enough to compare the available indicators with those specified by the manufacturer. But only specialist with appropriate training should to carry out all calculations and checks.

All contacts, terminals, sensors, starters, connections and adjoinings are checked in parallel. The power cord must be hermetically sealed and the junction box securely fastened to the housing. Shut-off valves, mechanical fasteners, couplings, non-return valves are also checked.

An important nuance in the maintenance of sewage pumping stations – compliance with safety measures. The pump needs to be repaired if its performance deviates from the standard by at least 10%. Visual inspection helps to detect mechanical damage and traces of corrosion. In the presence of rust, it is carefully removed, and the pump is treated with anti-corrosion substances.

Our company “Aquapolymer Engineering” offers the equipment and accessories for sewer systems and treatment facilities of household or industrial function, and also – the whole complex of auxiliary services.