Wastewatrer entering the sewer system almost always contains various greases. This is especially true of kitchen drains, both domestic and professional.

Subsequently, a large amount of grease clogs the sewer system, impairs its operation and efficiency of treatment plants. Greases are deposited in tanks and on the drainage surface, polluting the environment, soil and water. Sewage pumping is also complicated.

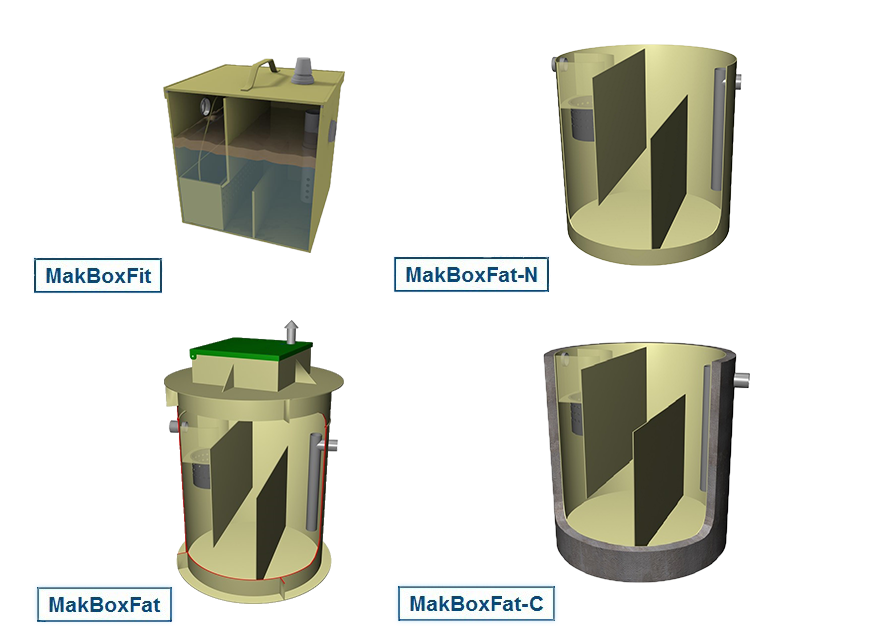

This is why grease separsators are used in sewer systems. Their basic principle is as simple as possible: they retain grease particles and prevent them from entering the sewer network. But the design features may differ.

Water, getting into the tank, gradually fills the first chamber. Grease particles rise to the surface due to different densities. There, the grease enters a special tray, where it accumulates, and the purified water goes further through the system. In the second chamber, the grease is finally separated. Accumulated solid particles must be periodically cleaned manually or with the help of automated systems.

An additional mechanical filter is often installed in grease separators. It eliminates the largest particles in front of the inlet pipe to prevent premature contamination.

An important nuance is the complete tightness of the structure. This prevents the risk of waste leakage, prevents the spread of odors, makes the grease separator really effective and environmentally friendly. The diameters of the branche pipes are selected according to the diameter of the pipeline for ease of installation and reliability of connections.

Work technology

Different models of grease separators use different methods for separating and processing grease:

- Mechanical. Fine-grained porous membranes contain fatty compounds. This is the simplest method that can be used in any environment, but it is not effective enough for large amounts of work. If there is too much grease, the membranes become clogged quickly and require constant cleaning and replacement.

- Coalistic. Another natural way. Greases are collected in conglomerates, accumulate on the surface, form a film, and then removed mechanically.

- Physico-chemical. The system uses special reagents that bind grease particles together. And mechanical deep cleaning filters separate large accumulations and deposit them in settling tanks.

- Flotation. Special compressors are pumped air into the chamber. Greases accumulate in bubbles and then rise to the surface. The method is used in systems with high effluent temperature, when the grease is almost completely dissolved and mechanical methods are not effective enough.

- Centrifugation. Water and grease have different densities and weights, so that entering the centrifuge, they are separated under the influence of inertia.

There are also grease separators that are based on the principle of evaporation, crystallization and other modern technologies. They are selected taking into account the operating conditions, type and properties of the working environment, the expected level of loads and capacity.

The Aquapolymer Engineering company offers reliable complex systems for the arrangement of wastewater treatment plants of industrial and household function of various complexity.